CHOOSE THE AXLE SERIES

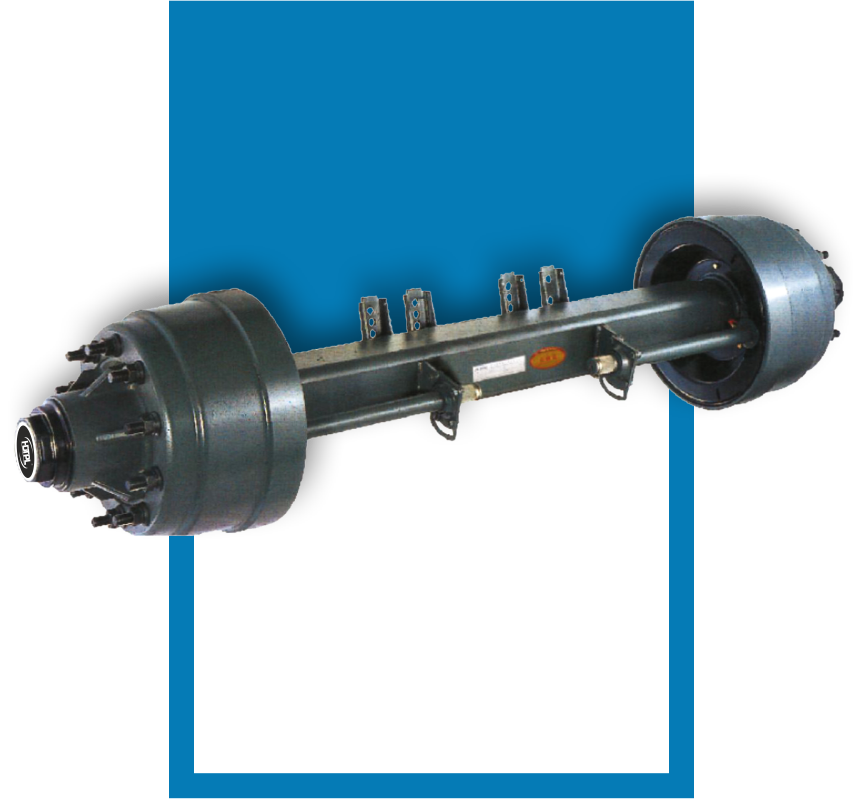

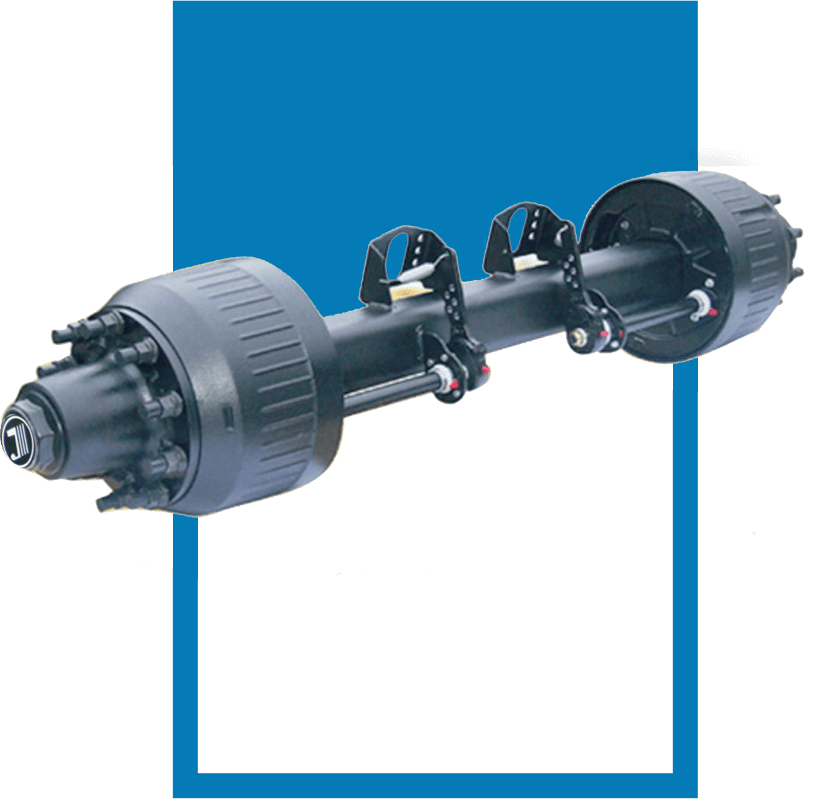

American ECO Axle

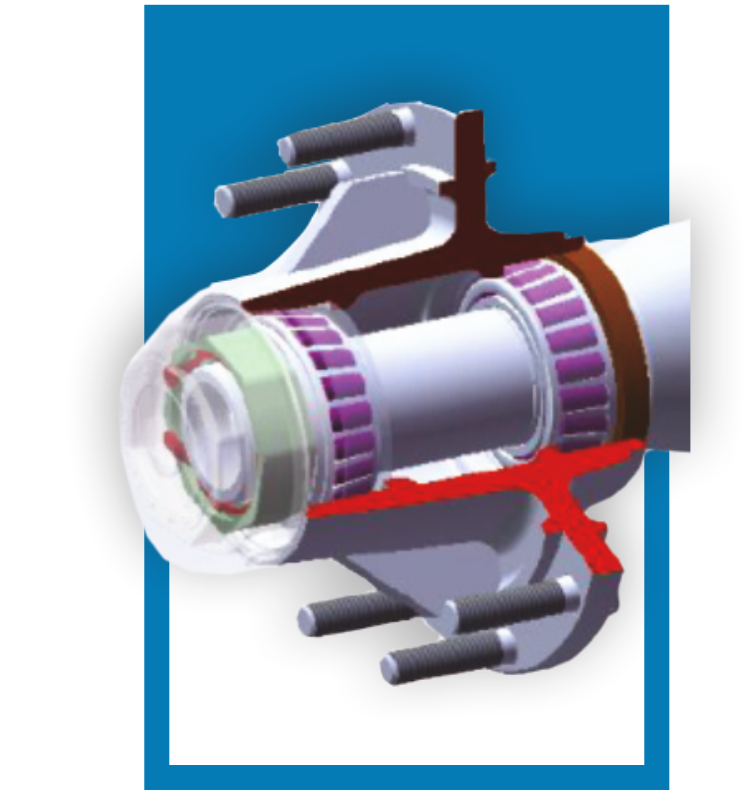

Structure Characteristics

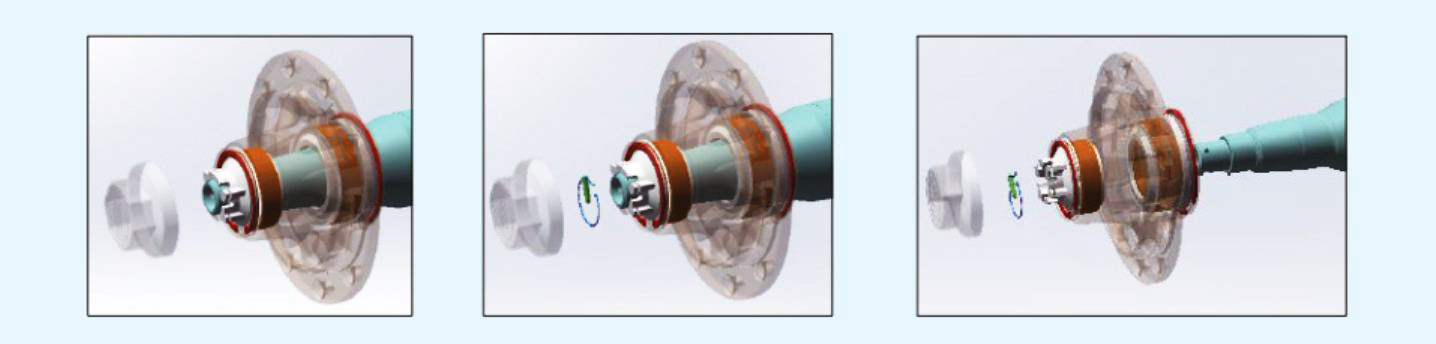

1. Without special removal tool assembly and disassembly of the eco hub system only hub cap and axle nut wrench each one can be in any place disassembly.

2. Internal and external bearing hole with elastic ring bearing and hub are fixed into a whole body, axle in maintenance disassembly process, inner and outer bearing will not be apart.

3. ECO axle maintenance easy to disassemble, effectively reduce the maintenance time, greatly improve the working efficiency of the replacement of the brake pad.

4. To extend the service life of the bearing: bearing into the wheel system grease, special structure can effectively prevent dust and water erosion, better to extend the service life of the bearing obviates the regular lubrication and maintenance.

5. Bearing is the standard Matric tapered roller bearings, can be purchased in any place according to the bearing model.

6. ECO axel assembly and disassembly steps as shown in figure (1 ,2,3).